Simatech shipping, UAE

Trading in shipbuilding equipment involves facilitating the sale and purchase of various tools, machinery, and components used in the construction, repair, and maintenance of ships. This can include everything from large-scale equipment like cranes, welding machines, and propulsion systems to smaller items like valves, pumps, and electrical components. As a trader in this industry, VALVES LLC liaises with shipyards, maritime engineering firms, shipping companies, and suppliers to source and distribute the necessary equipment. Knowledge of maritime regulations, industry standards, and emerging technologies would be essential to effectively serve your clients and stay competitive in the market. Additionally, building strong relationships with manufacturers and understanding the specific needs of your customers would be crucial for success in this field. At VALVES LLC, we specialize in supplying a wide range of maritime items including:

Pumps: Centrifugal pumps, diaphragm pumps, gear pumps, and hydraulic pumps.

Pipes and Fittings: Pipes, couplings, flanges, elbows, tees, and reducers.

Actuators and Controls: Electric actuators, pneumatic actuators and control valves.

Marine Equipment: Anchors, chains, ropes, winches, and navigational equipment.

Marine Safety Equipment: Life rafts, life jackets, life buoys, PPE.

Navigation and Communication Systems: GPS Systems, radar systems, VHF radios.

Deck Machinery and Equipment: Winches, cranes, capstans and anchor equipment.

Marine Electronics and Instrumentation: Sonar systems, depth sounders, underwater cameras, weather monitoring systems, data acquisition systems.

All our products undergo rigorous quality checks to ensure reliability and durability. With a vast network of suppliers and partners, we can deliver spare parts to any location worldwide. We offer competitive prices without compromising on quality, ensuring value for our customers. Our dedicated team provides excellent customer support, assisting you with product selection, technical queries, and after-sales service.

In the vast expanse of marine engineering, ensuring the smooth operation and safety of vessels is paramount. At the heart of this intricate machinery lie marine valves, the unsung heroes regulating flow, pressure, and direction of fluids onboard. VALVES LLC serves as your compass through the labyrinth of marine valve solutions, illuminating their importance, types, applications, and the critical role they play in maritime operations. Marine valves are essential components designed to control the flow of liquids or gases within a ship's piping system. These valves serve various functions, including regulating fluid flow, isolating sections of pipelines, and preventing backflow, all vital for the safe and efficient operation of vessels.

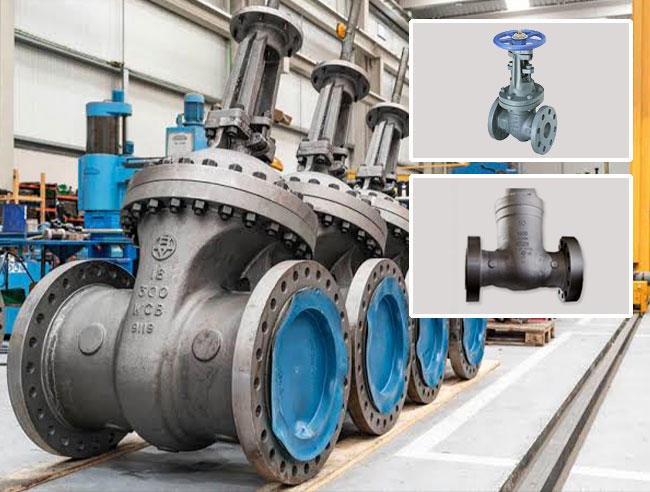

Gate Valves:

Gate valves are linear motion valves that regulate the flow of fluids by raising or lowering a gate or wedge across the path of the flow. They are primarily used to start or stop the flow, rather than regulate it. Gate valves are commonly employed in systems where the flow needs to be completely shut off, such as in water treatment plants, oil refineries, chemical processing plants, and more.

Gate valves are available in various materials, including cast iron, ductile iron, carbon steel, stainless steel, and exotic alloys. The choice of material depends on the fluid being handled, temperature, pressure, and environmental conditions.

Gate valves come in a range of sizes and pressure ratings to accommodate different system requirements. It’s crucial to select the appropriate valve size and pressure rating to ensure reliable performance and safety.

Gate valves are available with different end connections, such as flanged, threaded, or welded ends. The selection of end connections depends on the piping system and installation requirements.

Ball Valves: Featuring a spherical closure unit, ball valves offer quick and reliable shut-off. Their compact design and minimal leakage make them ideal for high-pressure applications, like fuel systems and hydraulic circuits.

Ball valves are quarter-turn valves that utilize a hollow, perforated, and pivoting ball to control the flow of fluids. The ball inside the valve has a hole or port through which the fluid passes when the valve is open. Ball valves are highly versatile and widely used in applications where tight shut-off and reliable flow control are essential.

Floating Ball Valves: In floating ball valves, the ball is suspended in the flow medium by the pressure of the fluid. This design allows the ball to move freely within the valve body, ensuring tight sealing when the valve is closed.

Trunnion Ball Valves: Trunnion ball valves feature a fixed ball supported by trunnion bearings or a trunnion-mounted stem. This design enhances stability and performance, making trunnion ball valves suitable for high-pressure and high-temperature applications.

V-port Ball Valves: V-port ball valves have a V-shaped ball orifice, which enables precise control of flow rates. These valves are commonly used in applications requiring modulating flow control, such as in chemical processing and industrial automation systems.

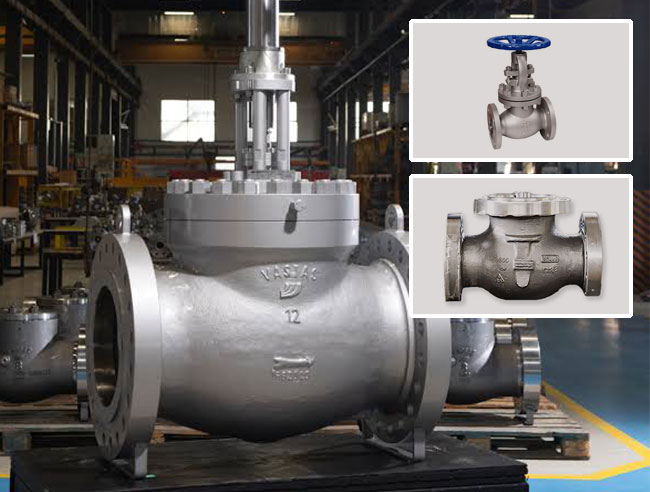

Globe Valves:

Globe valves are linear motion valves that regulate the flow of fluids by moving a disc or plug in and out of the flow stream. They are characterized by their spherical body shape and are widely used in applications requiring precise flow control and throttling. Globe valves offer excellent shut-off capabilities and are commonly found in industries such as oil and gas, power generation, and water treatment.

Straight pattern globe valves have a streamlined body design with the inlet and outlet in line with each other. These valves are compact and suitable for applications with limited space.

Angle pattern globe valves feature an angled body design, with the inlet and outlet at a 90-degree angle. This configuration allows for easier access to the valve stem and is commonly used in applications where space is limited or flow direction needs to be changed.

Bellows seal globe valves incorporate a flexible metal bellows seal to prevent leakage around the valve stem. These valves are ideal for applications handling corrosive or hazardous fluids and where zero stem leakage is required. Pressure seal globe valves feature a unique design with a bonnet that is bolted directly to the valve body, creating a pressure-tight seal. These valves are suitable for high-pressure and high-temperature applications, such as steam service and power generation.

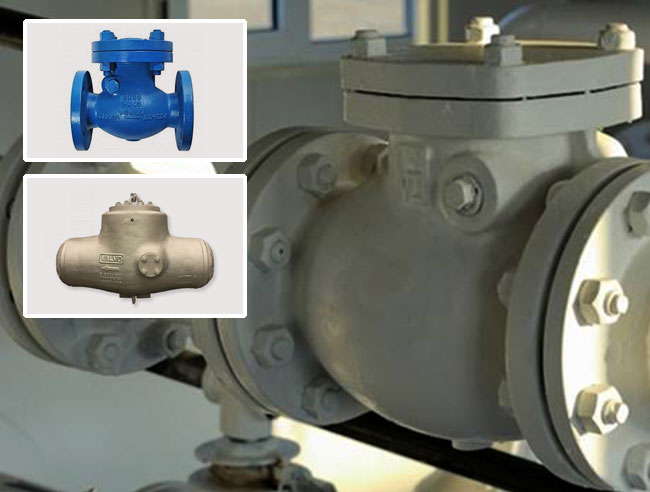

Check Valves: Check valves, also known as non-return valves or one-way valves, are mechanical devices designed to allow fluid flow in one direction while preventing reverse flow. They operate automatically and are crucial components in systems where backflow prevention is essential, such as pumping stations, wastewater treatment plants, chemical processing facilities, and more.

Swing check valves feature a hinged disc that swings open in the direction of flow and closes to prevent reverse flow. They are simple in design, reliable, and suitable for applications with moderate to high flow rates.

Lift check valves utilize a disc or piston that lifts away from the seat to allow forward flow and drops back into place to prevent backflow. They are commonly used in applications with vertical flow and high-pressure conditions.

Tilting disc check valves employ a disc that pivots on a hinge at the top of the valve body. When fluid flow stops, gravity causes the disc to tilt and close the valve, preventing reverse flow. These valves are ideal for high-pressure applications and provide low head loss. Spring-loaded check valves feature a spring mechanism that applies force to keep the valve closed until the pressure exceeds a certain threshold. They are versatile and suitable for a wide range of applications, including low-pressure systems.

Butterfly Valves: Butterfly valves feature a disc mounted on a rotating shaft, controlling flow via a quarter-turn motion. Their lightweight and compact design make them popular for applications requiring rapid operation, such as tank ballasting and cargo handling.

They are known for their compact design, quick operation, and excellent flow control capabilities. Butterfly valves are widely used in various applications, including water treatment, HVAC systems, chemical processing, and more.

Wafer-type butterfly valves are designed for installation between flanges in pipeline systems. They feature a thin profile, making them lightweight and easy to install. These valves are ideal for applications with limited space and moderate pressure ratings.

Lug-type butterfly valves have threaded inserts (lugs) on the valve body, allowing for easy installation and removal from the pipeline without disturbing the flanges. They provide a secure connection and are suitable for applications where the valve needs to be anchored to the pipeline. Double offset butterfly valves have a disc offset from the centerline of the valve body and the stem offset from the centerline of the disc. This design reduces friction during operation, resulting in improved sealing performance and extended service life. Double offset butterfly valves are suitable for high-pressure and high-temperature applications.

Selecting the appropriate marine valves requires careful consideration of factors such as operating conditions, fluid characteristics, system requirements, and regulatory compliance. Collaborating with reputable manufacturers and consulting experienced marine engineers can help ensure the selection of valves optimized for performance, reliability, and safety in maritime applications. As you traverse the vast oceans, navigating through challenges and triumphs, let marine valves be your steadfast companions, guiding the flow of fluids and safeguarding the integrity of your vessel. With a myriad of options available, choosing the right valves tailored to your specific needs is paramount for smooth sailing and operational excellence. Allow us to use VALVES LLC’s expertise in this field from 2017 supporting the maritime industry of the Middle East especially that of UAE & Oman for all your requirements,

A Few Companies Associated with Us

-

-

GFS Ship Management, UAE

-

Interworld Shipping, UAE

-

Geo Sea Foods, India

-

Simamarine Shipping, India

-

Monsun Marine, India

-

CNJ Valves, Korea

-

DK Valves, Korea

-

Dikkan Valves, Turkey

-

Drydocks World, Dubai